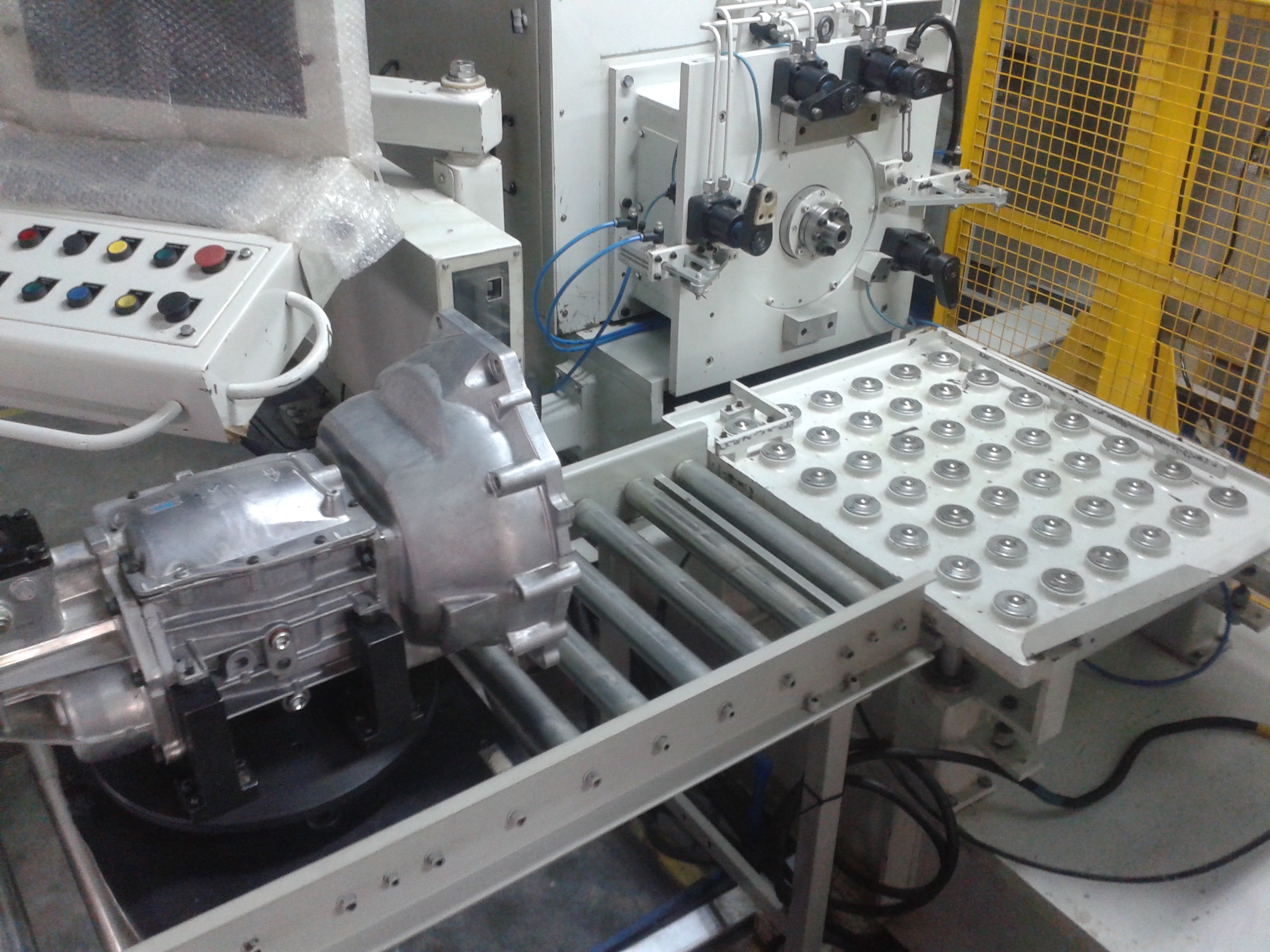

Ball Transfer Tables

Ball Transfer Tables Specification

- Thickness

- 5 mm Ball Plate Millimeter (mm)

- Features

- 360-degree Load Movement, Low Maintenance, Heavy Duty

- Power Source

- Manual

- Surface Finish

- Powder Coated

- Material

- MS

- Type

- Roller Conveyor

- Structure

- Roller

- Roller Conveyor

- Yes

- Resistant Feature

- Corrosion Resistant

- Load Capacity

- 150 kg per Ball Transfer Kilograms (kg)

- Power

- Volt (v)

- Usage & Applications

- Material Handling, Assembly Lines, Packaging, and Sorting Areas

- Frame Material

- Mild Steel Channel

- Ball Diameter

- 25 mm

- Table Width

- 600 mm (Standard, Custom Available)

- Finish Color

- Grey or Customized

- Operating Temperature

- -10C to 80C

- Installation Type

- Floor Mounted

- Table Length

- 1200 mm (Standard, Custom Available)

- Table Height

- 750 mm

- Number of Balls per Table

- Customizable

Ball Transfer Tables Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5 Units Per Month

- Delivery Time

- 3-4 Week

About Ball Transfer Tables

Ball Transfer Tables

With wide and industrial experience we are able to offer Complete Solutions in Ball Transfer Tables, turn table, BAL transfer unit, and Lift tables. We produce these types of Elbow Blocks using excellent quality of steels and raw materials sourced from leading vendors. Our firm has featured this with stiff body for prolonged usage, adjustable clamps, portable wheel base etc. These are applicable in all scale industries.

Specifications

|

Height from bottom of frame to top of roller |

183 mm |

|

Brand |

Tantra India |

|

Static Load Per Roller |

30 kg |

|

Roller Pitch |

75 mm |

|

Material |

Stainless Steel |

Efficient Material Handling Solution

Ball Transfer Tables offer seamless, multidirectional movement for goods, making them ideal for sorting, assembly, and packaging applications. With a heavy-duty mild steel frame and corrosion-resistant, powder-coated finish, they ensure durability and low maintenance. Each ball transfer supports up to 150 kg, and the customizable layout adapts to various operational needs.

Customizable Design for Various Workspaces

Standard sizes measure 1200 mm in length and 600 mm in width, but tables can be tailored to specific dimensions and ball quantities. Flexible installation as floor-mounted units, combined with options for finish color, allow integration into diverse industrial environments, ensuring a perfect fit for your material handling workflow.

Performance in Diverse Conditions

Engineered for reliability, these tables operate smoothly within a temperature range of -10C to 80C. The 5 mm thick ball plate and sturdy build guarantee consistent performance even in demanding industrial settings. The manual operation ensures safety and speed control, making it versatile for both light and heavy-duty tasks.

FAQs of Ball Transfer Tables:

Q: How do Ball Transfer Tables facilitate 360-degree load movement?

A: Ball Transfer Tables incorporate spherical ball transfers embedded into a robust frame, enabling items to glide smoothly in any direction. This multidirectional movement allows operators to effortlessly shift, rotate, or position products across processing, assembly, or packaging areas, streamlining workflows and minimizing manual lifting.Q: What customization options are available for these Ball Transfer Tables?

A: You can customize the tables length, width, number of ball transfers, and finish color based on your operational needs. While the standard size is 1200 mm by 600 mm, we fabricate tables in other dimensions as required, ensuring compatibility with various workspace layouts and tasks.Q: Where are Ball Transfer Tables typically installed and used?

A: These tables are commonly floor-mounted in locations such as assembly lines, packaging zones, sorting areas, and shipping departments. Their versatility and heavy-duty design make them ideal for various industries across India, particularly for manual material handling situations where flexibility and efficiency are paramount.Q: What is the recommended process for installing a Ball Transfer Table?

A: Installation involves positioning the table at the desired location and securing it to the floor using appropriate mounting hardware. Ensure the surface is level for optimal performance, and follow the provided instructions for anchoring and safety. This set-up process is quick and straightforward, enabling minimal disruption to operations.Q: How does the manual operation impact material handling speed and efficiency?

A: With manual operation, speed depends on the users push, offering precise control and enhanced safety in moving items across the table. This method reduces the need for powered systems, allowing quick loading, repositioning, and sorting of products while keeping maintenance costs low.Q: What key benefits do Ball Transfer Tables provide in industrial settings?

A: They offer 360-degree movement, rapid positioning, heavy-duty load capacity, and corrosion resistance, all while requiring minimal maintenance. These features facilitate smoother workflow, reduce physical strain on operators, and contribute to greater productivity in assembly, packaging, and sorting applications.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email